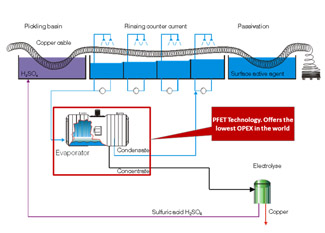

Recovery of Copper, Water and Sulphuric Acid in a copper cable manufacturing plant using our PFET technology

Recovery of Copper, Water and Sulphuric Acid from effluent generated during copper manufacturing

Challenge:

A copper manufacturer in Canada wanted to recover copper mixed in their rinse bath while manufacturing copper cables.

Solution:

PFET was installed to evaporate the rinse bath and copper mixture was obtained. This was electrolysed to obtain commercial grade copper. During electrolysis, spent sulphuric acid was recovered that was added back in the pickling basin. Through our evaporator, recovered condensate was recycled and used in the 4th stage of rinsing.

Impact:

By using our technology the company was able to recover-

- Commercial grade Copper from the rinse bath

- Water in the form of condensate, recycled for rinsing of copper cable

- Sulphuric Acid from the concentrate of our evaporator, recycled in the pickling basin